News

Lapidary Fundamentals: Cutting Rough Stones

If you’ve ever looked at a rough stone and wondered how to transform it into a polished gem, then “Lapidary Fundamentals: Cutting Rough Stones” is the article for you. This captivating piece explores a wide range of techniques and tools that will help you cut rough stones with precision and finesse. From using a rock hammer to break large rocks into smaller pieces, to creating a shallow saw cut called a kerf for greater control, this article covers it all. It also recommends the use of saws and tile nippers for cutting fragile gems and expensive pieces of rough. With detailed explanations of different types of saw blades, feeding and holding techniques, as well as maintenance practices, this article is your go-to guide for mastering the art of cutting rough stones.

Types of Cutting Tools

When it comes to cutting rough stones, having the right tools is essential. In this article, we will explore three types of cutting tools that are commonly used in lapidary work: the rock hammer, the saw, and tile nippers. Each tool has its own unique uses and advantages, so let’s dive in and learn more about them.

Rock Hammer

The rock hammer is a sturdy and versatile tool that is perfect for breaking large rocks into smaller pieces. Whether you’re dealing with a massive boulder or a stubborn piece of rough stone, the rock hammer can be your best friend. Its heavy head and strong handle make it easy to apply enough force to break even the toughest rocks.

Breaking Large Rocks

When you encounter a large rock that is too big to work with, the rock hammer comes to the rescue. By applying controlled strikes with the rock hammer, you can easily break the rock into manageable pieces. This allows you to work with smaller sections of the rough stone and makes the cutting process much easier.

Creating Smaller Pieces

In addition to breaking large rocks, the rock hammer is also great for creating smaller pieces from larger ones. Sometimes, you may have a rough stone that is too large to work with in its current form. By using the rock hammer, you can carefully chip away at the stone and create smaller, more manageable pieces that are easier to cut and shape.

Saw

The saw is a powerful cutting tool that offers precision and versatility. With the right technique and the right type of saw blade, you can cut through rough stones with ease. Let’s explore the different sawing techniques and the types of blades that can be used.

Cutting a Kerf

One of the most useful sawing techniques in lapidary work is cutting a kerf. A kerf is a shallow saw cut made in the stone, and it serves multiple purposes. First, it allows you to have greater control over the cutting process, as you can follow the line of the kerf with your saw blade. Second, it helps to prevent the stone from cracking or breaking in unexpected ways. By creating a starting point with a kerf, you can guide your saw along the desired path and achieve precise cuts.

Control and Versatility

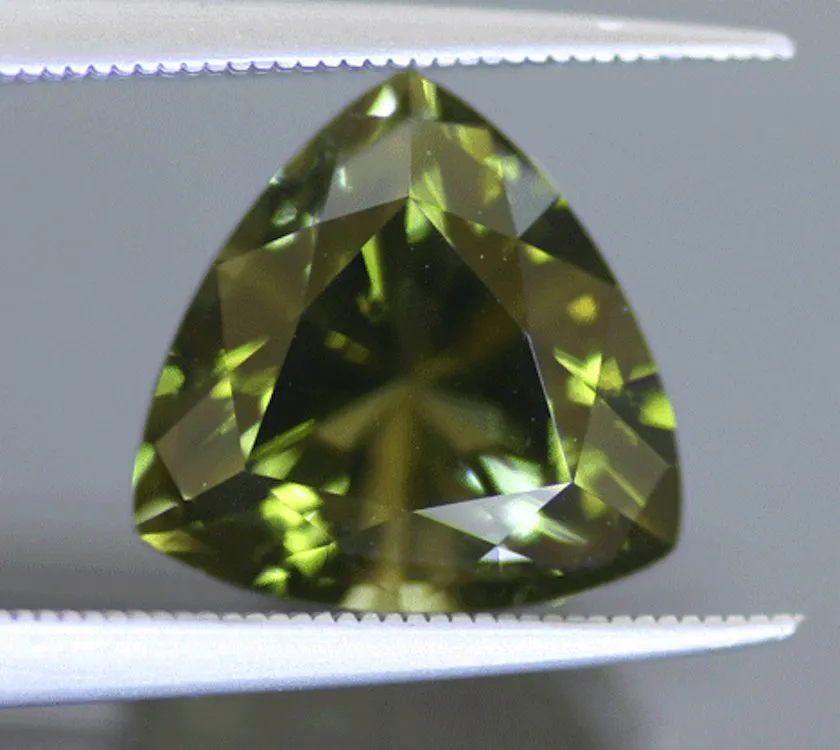

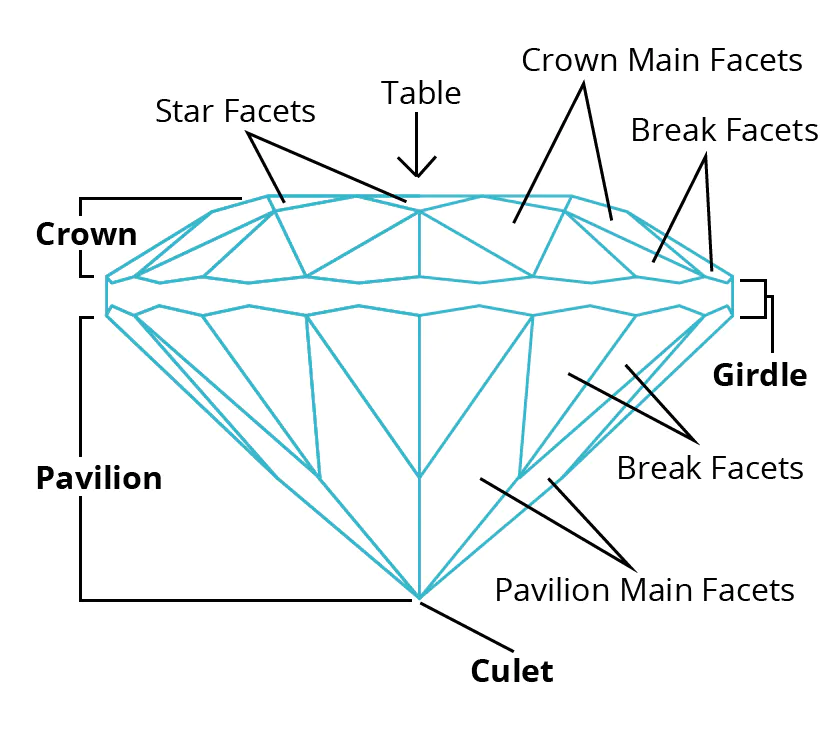

Another advantage of using a saw is the control and versatility it offers. Unlike a rock hammer, which can be limited in terms of the shapes and sizes it can create, a saw allows for more intricate and precise cuts. With the right technique and a steady hand, you can easily shape rough stones into various forms, such as cabochons or faceted gemstones. The versatility of a saw makes it a valuable tool for lapidary artists who work with a wide range of gemstones and designs.

Types of Saw Blades

Choosing the right saw blade is crucial for achieving optimal cutting results. Different types of saw blades are designed for specific purposes and materials. Let’s take a closer look at two popular types of saw blades for lapidary work: diamond blades and mud saws.

Diamond Blades

Diamond blades are known for their exceptional cutting ability. They are made with industrial-grade diamonds embedded in the edge, which gives them unparalleled strength and durability. Diamond blades are commonly used for cutting hard materials, such as granite, quartz, and other tough gemstones. Their sharp and precise cutting edges make them ideal for creating intricate designs and precise cuts.

Mud Saws

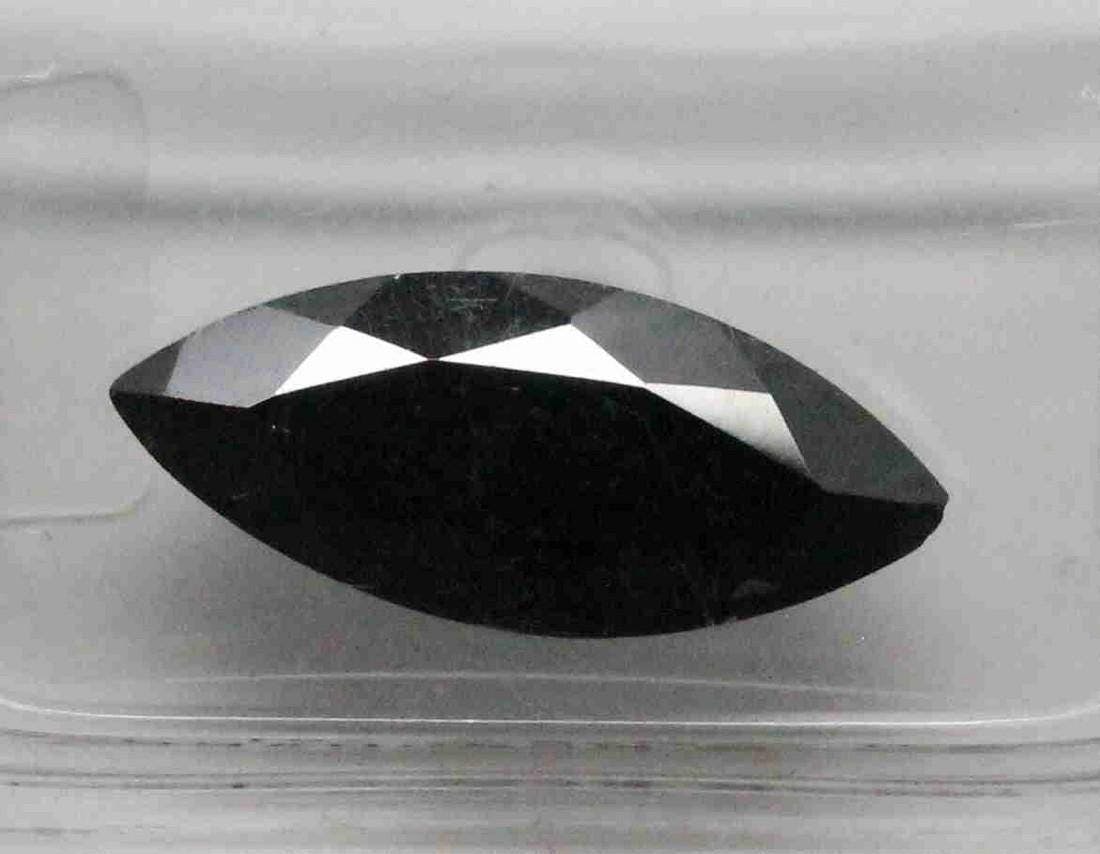

Mud saws, on the other hand, are designed for softer materials. These blades have a toothed edge that is coated with a mixture of grinding compound and water, creating a muddy slurry during the cutting process. Mud saws are excellent for cutting through materials like glass, ceramic, and softer gemstones. They provide a clean and smooth cut, making them a preferred choice for delicate and expensive rough stones.

Choosing the Right Blade

When it comes to choosing the right blade for your cutting needs, it’s important to consider the type of material you’ll be working with. Harder materials require diamond blades, while softer materials are better suited for mud saws. By selecting the appropriate saw blade, you can ensure optimal cutting performance and achieve the desired results.

Proper Feeding and Holding Techniques

Using a saw properly involves more than just selecting the right blade. Proper feeding and holding techniques are crucial for both the efficiency and safety of the cutting process. Let’s explore some key practices that you should keep in mind.

Preventing Blade Damage

To prevent damage to the saw blade, it’s important to feed the material steadily and evenly. Applying too much pressure or sawing too quickly can cause unnecessary strain on the blade and may result in a broken or damaged blade. Make sure to let the blade do the work and avoid forcing it through the material. Additionally, it’s important to check the saw blade regularly for any signs of wear or damage, and replace it when necessary.

Ensuring Precision and Safety

Alongside preventing blade damage, proper feeding and holding techniques also ensure precision and safety. By holding the rough stone securely and guiding it smoothly through the saw, you can achieve accurate cuts and minimize the risk of accidents. Always use a saw vise or clamp to hold the material in place and keep your fingers at a safe distance from the saw blade. Remember to wear protective goggles and other safety gear to safeguard yourself during the cutting process.

Saw Maintenance

Proper maintenance of your saw is essential to keep it in optimal working condition. By following a few simple maintenance practices, you can prolong the lifespan of your saw and ensure consistent cutting performance.

Lubrication

Lubricating your saw is vital to reduce friction and heat during the cutting process. This helps to prevent the saw blade from overheating and ensures smooth and efficient cutting. Make sure to use an appropriate lubricant for your saw, as different types of saw blades may require different lubricants. Apply the lubricant regularly and as per the manufacturer’s instructions to keep the saw running smoothly.

Regular Cleaning

Regular cleaning of your saw is also important to remove debris, grit, and other particles that can accumulate on the blade and affect its cutting performance. After each use, make sure to clean the blade with a soft brush or cloth, removing any residue or buildup. This will not only keep the blade clean but also prevent potential damage to the blade caused by abrasive particles.

Using Tile Nippers

Tile nippers are a handy tool for cutting fragile gems and expensive pieces of rough. These small, handheld tools allow for precise material removal and can be a great addition to your lapidary toolkit.

Material Removal

Sometimes, you may need to remove small amounts of material from a rough stone to shape it according to your design. This is where tile nippers come in handy. With their pointed jaws, tile nippers can carefully chip away at the stone, allowing you to shape it with precision. This is particularly useful when working with delicate and valuable gemstones that require gentle handling.

Splitting Fractured Gems

In addition to material removal, tile nippers are also effective for splitting fractured gems. Instead of trying to mend a fractured stone, you can use tile nippers to separate the fractured pieces, creating smaller, more manageable stones. This can save you time and effort, as well as allow you to salvage some usable material from a damaged gem.

Grinders Mention

While grinders are mentioned as a tool for shaping and smoothing stones, they are not further discussed in this article. Grinders are another powerful tool that can be used in lapidary work to shape and polish rough stones. They are particularly useful for creating cabochons and other curved shapes. However, due to the scope of this article, we will not delve into the specifics of using a grinder.