News

Lab-grown diamond production methods simulate the natural conditions for diamond formation

Lab-grown diamond production methods are designed to replicate the natural conditions that lead to the formation of diamonds deep underground. These methods, which include high pressure/high temperature (HPHT) and chemical vapor deposition (CVD), result in synthetic diamonds that possess the same properties as their natural counterparts. While HPHT is primarily used for industrial purposes, CVD is favored for producing gem-quality synthetic diamonds for use in jewelry. Gemologists can differentiate between natural and lab-grown diamonds by closely inspecting their crystal shapes. Additionally, both HPHT and CVD diamonds undergo additional treatments to enhance their color and clarity.

Lab-grown diamond production methods

Introduction

Diamonds have long been treasured for their beauty and rarity, but advancements in technology have made it possible to create diamonds in a laboratory setting. Lab-grown diamonds are created by simulating the natural conditions that produce diamonds underground. These synthetic diamonds have the same physical and chemical properties as natural diamonds, but they are made in a much shorter time frame. There are two main methods used in the production of lab-grown diamonds: High Pressure/High Temperature (HPHT) and Chemical Vapor Deposition (CVD).

HPHT method

The HPHT method is commonly used for industrial purposes and has been used for many years to create synthetic diamonds. The process involves placing a carbon starting material, metal flux, and a diamond seed in a press. The press then heats the materials to extremely high temperatures and applies high pressure to simulate the conditions under which natural diamonds form deep underground. Through this process, lab-grown diamonds are created.

Materials and process

In the HPHT method, the carbon starting material can be graphite or a diamond seed. The metal flux, usually made up of nickel or cobalt, acts as a catalyst to facilitate the growth of the lab-grown diamond. The materials are placed in a press, which then heats them to temperatures around 1,500 degrees Celsius and subjects them to pressures of about 5 to 7 GPa. These intense conditions cause the carbon atoms to rearrange and bond, forming a crystal lattice structure that results in the growth of a diamond.

Application in industry

The HPHT method is widely used in the industrial sector for various purposes. Synthetic diamonds created using this method have properties that make them suitable for use in cutting tools, drilling equipment, and abrasives. They are also used in specialized applications such as high-power electronics and advanced optics. The ability to create diamonds with specific properties through the HPHT method has revolutionized several industries.

CVD method

The CVD method, on the other hand, is more popular for producing gem-quality synthetic diamonds for the jewelry industry. This method involves filling a chamber with a mixture of gasses, including a carbon-containing gas and a small amount of a diamond initiator. The chamber is then heated to high temperatures, typically around 800 to 1,000 degrees Celsius. As the gases decompose, carbon atoms are deposited onto a substrate, which acts as a starting point for diamond growth.

Materials and process

In the CVD method, the carbon-containing gas can be methane or a mixture of hydrocarbon gases. The diamond initiator is typically a small, high-quality diamond seed. The gas mixture is introduced into a chamber, where it is heated to the desired temperature. The carbon atoms from the gas decompose and settle onto the substrate, layer by layer, building the lab-grown diamond. The process can take several weeks to several months, depending on the desired size and quality of the diamond.

Application in jewelry industry

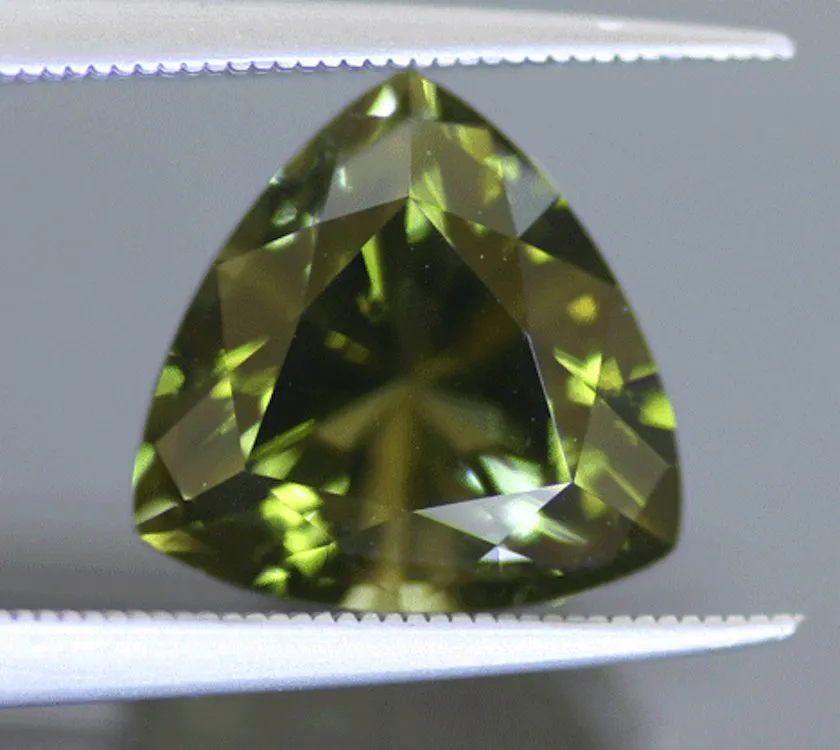

CVD diamonds have gained popularity in the jewelry industry due to their high quality and gemological characteristics. They possess the same physical, chemical, and optical properties as natural diamonds and are indistinguishable to the naked eye. CVD diamonds are used to create stunning and ethically sourced diamond jewelry, providing an alternative to mined diamonds. The controlled growth process of CVD diamonds allows for the creation of larger and more colorless diamonds, meeting the demands of consumers looking for high-quality gemstones.

Properties of lab-grown diamonds

Lab-grown diamonds share many similarities with natural diamonds in terms of their physical and chemical properties. They have the same crystal structure, hardness, and brilliance as natural diamonds. Gemologists use advanced techniques to distinguish between natural and lab-grown diamonds, primarily through their crystal shapes. Natural diamonds often have unique crystal structures, while lab-grown diamonds tend to have more regular and uniform shapes. However, this distinction is not noticeable to the untrained eye, making lab-grown diamonds a viable alternative to natural diamonds.

Comparison to natural diamonds

Lab-grown diamonds and natural diamonds share a multitude of similarities, making it difficult to differentiate between the two without specialized equipment. Both types of diamonds have the same atomic structure, refractive index, and dispersion. They also have similar hardness on the Mohs scale, with both being extremely durable. These similarities allow lab-grown diamonds to be used in the same applications as natural diamonds, including jewelry, industrial tools, and scientific instruments.

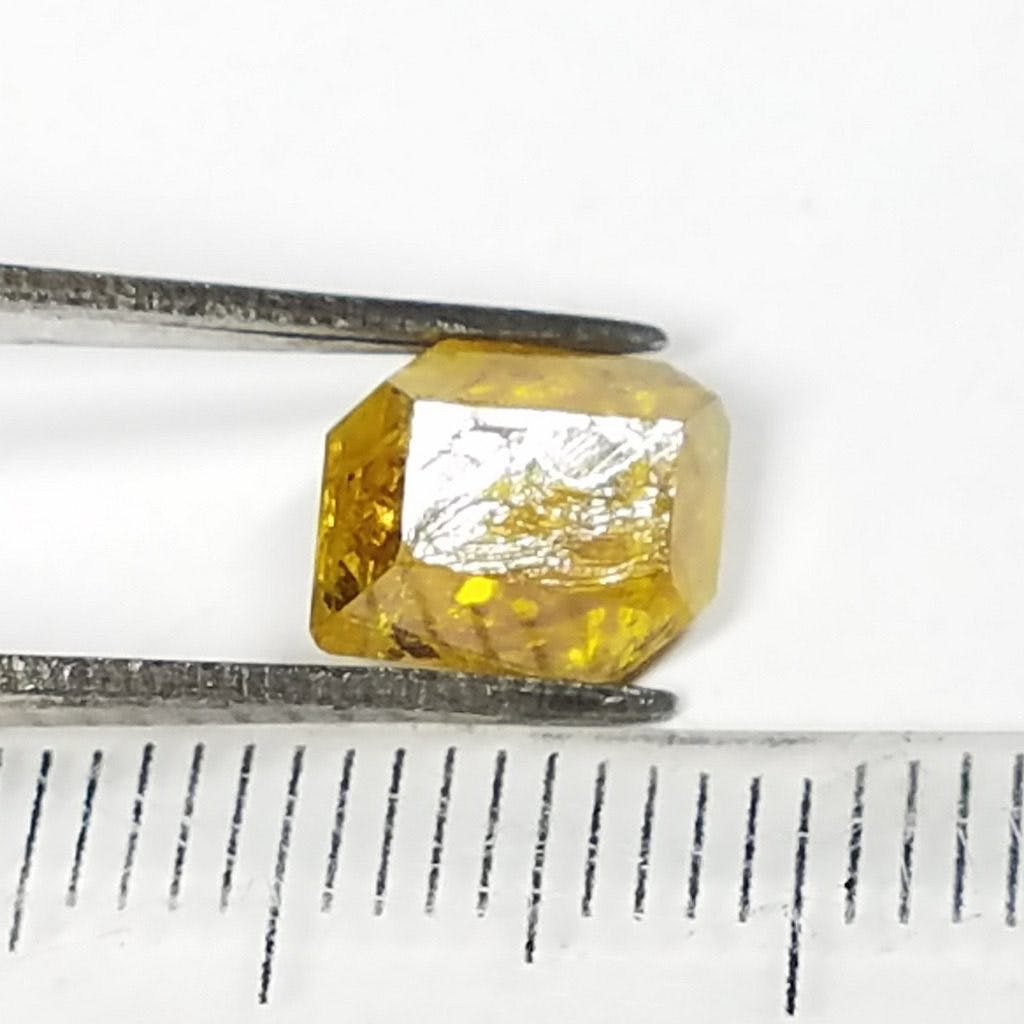

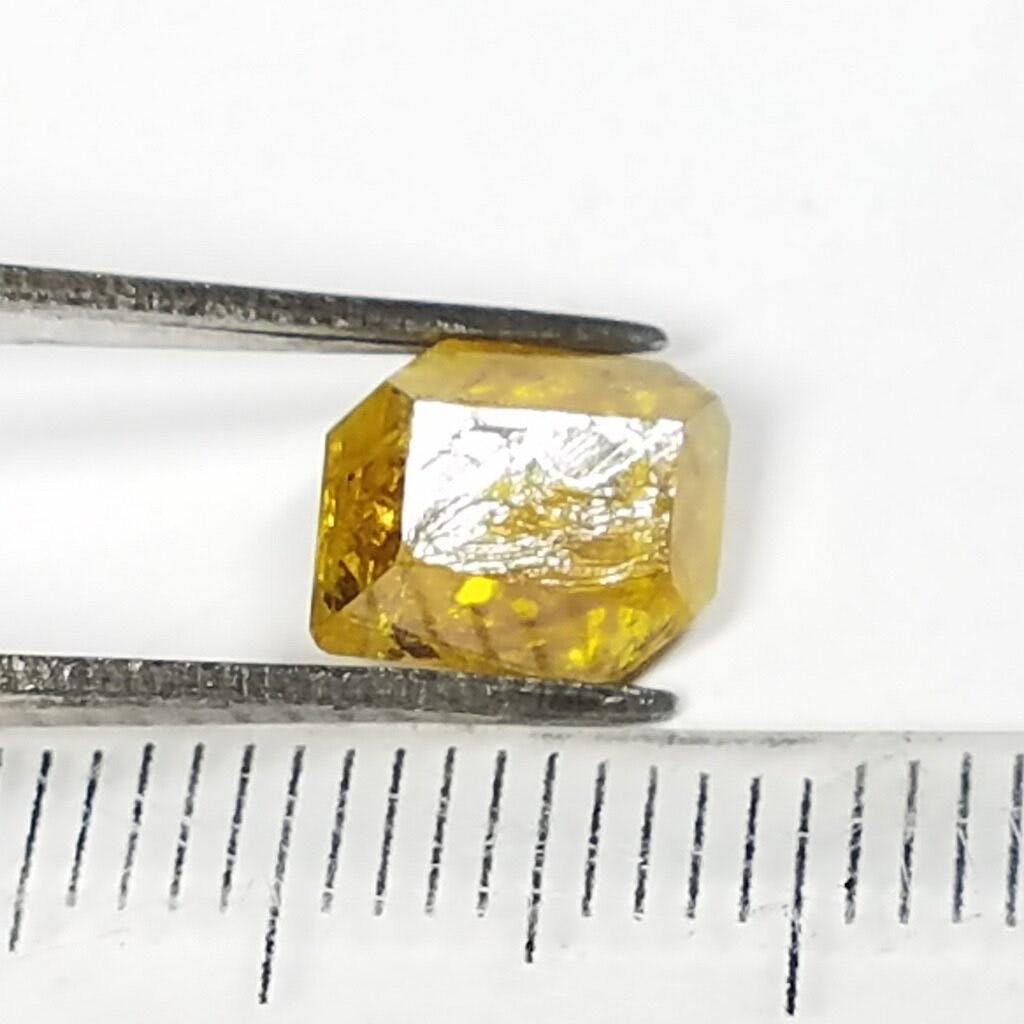

Distinguishing lab-grown diamonds

While lab-grown diamonds possess many of the same properties as natural diamonds, there are certain characteristics that can help gemologists identify them. The absence of certain impurities and the presence of certain growth patterns can indicate that a diamond is lab-grown. In addition, advanced spectroscopy techniques can reveal differences in the isotopic composition of lab-grown diamonds compared to natural diamonds. However, these distinctions require specialized equipment and expertise, and most consumers are unable to distinguish between the two types of diamonds without assistance.

Comparison to natural diamond formation

Although lab-grown diamonds use a different process to form compared to natural diamonds, they still replicate the conditions under which natural diamonds are created. Both HPHT and CVD methods aim to mimic the high pressure and temperature conditions deep underground. By providing these simulated environments, lab-grown diamonds can be produced with the same physical and chemical characteristics as their natural counterparts.

Similarities

Both lab-grown and natural diamonds form when carbon atoms are subjected to extreme pressure and temperature over long periods of time. The crystal lattice structure of diamonds is formed by the strong bonds between carbon atoms. This process occurs deep within the Earth’s mantle, where the pressure is immense and the temperatures reach thousands of degrees Celsius. Lab-grown diamonds recreate these conditions in a controlled environment, allowing for the creation of diamonds with the same atomic structure as natural diamonds.

Differences

The main difference between lab-grown and natural diamond formation lies in the time frame. While natural diamonds take millions of years to form, lab-grown diamonds can be created within a matter of days or months, depending on the method used. This accelerated growth process is made possible by providing the necessary pressure and temperature conditions in a controlled laboratory setting. Additionally, the absence of impurities and the elimination of the natural carbon cycle result in lab-grown diamonds that are often more consistent in color and clarity compared to natural diamonds.

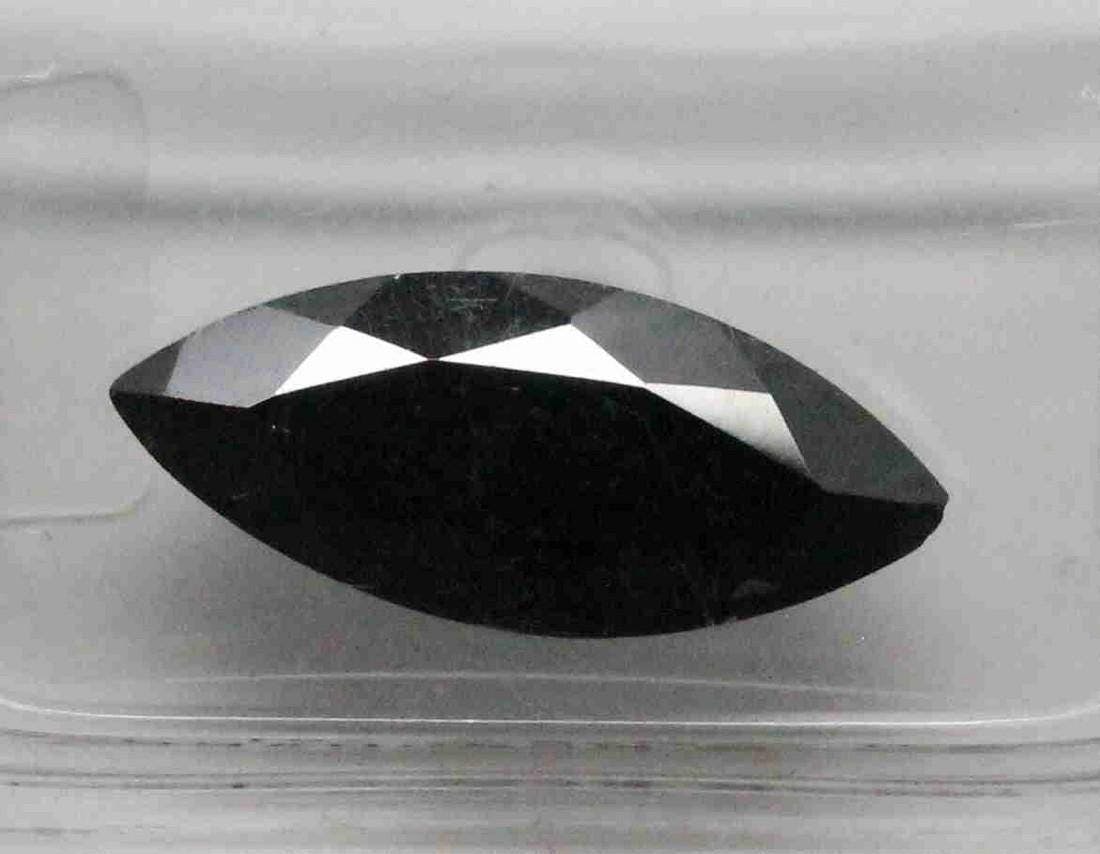

Additional treatments

Both HPHT and CVD lab-grown diamonds can undergo additional treatments to enhance their color and clarity. These treatments are similar to the processes used to enhance natural diamonds. For example, lab-grown diamonds can be subjected to high temperatures and controlled environments to improve their color, making them more appealing to consumers. Similarly, treatments can be applied to improve the clarity of lab-grown diamonds by removing any internal or external flaws. These enhancements allow lab-grown diamonds to match the desired specifications of consumers in terms of color and clarity.

Lab-grown diamond production methods have revolutionized the diamond industry by providing an ethical and sustainable alternative to mined diamonds. Through the HPHT and CVD methods, diamonds with the same physical and chemical properties as natural diamonds can be created. These lab-grown diamonds are used in various industries, ranging from industrial applications to exquisite jewelry. The ability to replicate the conditions that produce diamonds deep underground has opened up new possibilities and expanded the accessibility of diamonds to a wider market. As technology continues to advance, the production of lab-grown diamonds is expected to grow, offering a sustainable future for the diamond industry.